Key Takeaways

- Custom ribbon cable assemblies offer precise and reliable connections tailored to specific electronic system requirements in industries such as automotive, medical, and telecommunications.

- These assemblies improve signal integrity and reduce crosstalk and electromagnetic interference (EMI) through flat, parallel conductor layouts and custom shielding.

- Customization allows for exact specifications in length, pin configuration, insulation materials, and connector types, enabling efficient integration in high-density and miniaturized devices.

- Choosing a reputable manufacturer like Cloom Tech ensures compliance with UL/CSA standards, rigorous material testing, and quality assurance, leading to dependable performance and regulatory approval.

- Custom ribbon cable assemblies streamline installation and maintenance, reducing wiring errors, labor time, and facilitating quick deployment in complex systems.

Custom ribbon cable assemblies provide flat, multi-wire interconnections that ensure reliable signal transmission between electronic components in automotive, medical, and telecommunications applications. These flexible solutions offer precision fit, enhanced signal integrity, and streamlined installation through organised conductor layouts that reduce electromagnetic interference and crosstalk. Leading manufacturers like Cloom Tech produce Custom Ribbon Cable Assemblies with UL/CSA compliance, supporting diverse industrial sectors requiring high-performance electronic connections.

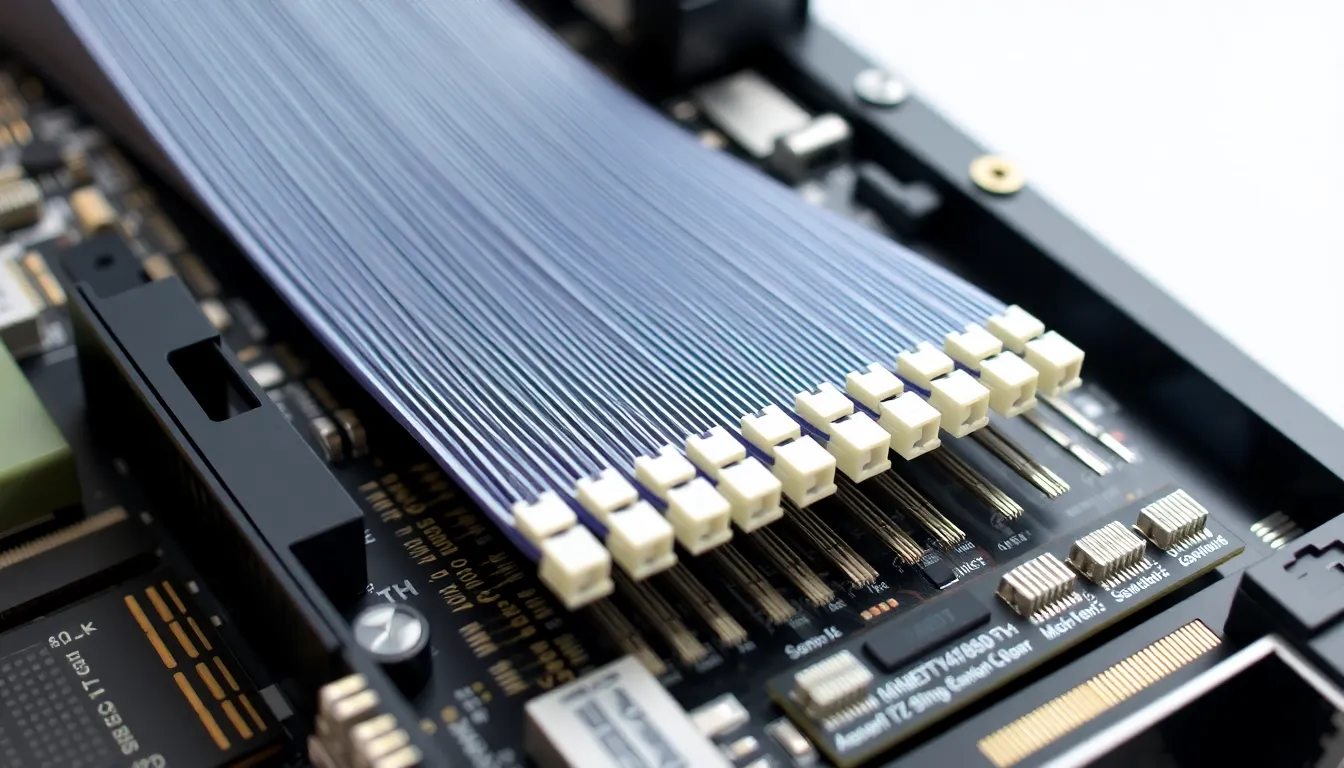

Understanding Custom Ribbon Cable Assemblies

Custom ribbon cable assemblies provide flat, multi-wire interconnections for electronics, ensuring clear signal transmission between circuit boards or devices. Each conductor in a ribbon cable runs parallel, giving the assembly its distinctive flat profile and allowing precise organization in dense systems. Engineers can select pin counts, spacing, insulation types, and termination methods for each custom ribbon cable, depending on circuit requirements. Common terminations include IDC (Insulation Displacement Connector), D-sub, and socket-style connectors, supporting integration into automotive controls, medical imaging equipment, and industrial automation systems.

Cloom Tech in Florida manufactures custom ribbon cable assemblies to exact client standards, including unique wire gauges, color coding, and EMI protection. Clients send design requirements, such as high-current capacity or miniature pitches; engineers apply these to meet application-specific electrical and spatial constraints. Cloom Tech’s process includes material testing, secure labeling, and UL/CSA-compliant fabrication, supporting dependable installation in robotics, computing hardware, and aerospace assemblies.

This customized approach delivers consistent electrical performance, reduces installation time, and lowers service errors. Assembly designers at Cloom Tech optimize cable routing paths, harness flexibility, and connector compatibility, supporting system-level efficiency. Custom ribbon cable assemblies from Cloom Tech accommodate evolving industry needs for miniaturization, power integrity, and quick deployment.

Key Benefits of Custom Ribbon Cable Assemblies

- Precision Fit for System Requirements

Custom ribbon cable assemblies allow engineers to specify exact length, pitch, conductor count, and termination types, matching the needs of distinct electronic systems like medical devices or control panels. Cloom Tech fabricates assemblies to these precise parameters, ensuring reliable fit and streamlined integration.

- Increased Signal Integrity

Flat, parallel conductor layouts reduce crosstalk and electromagnetic interference (EMI) risk in environments such as robotics or high-speed data equipment. Cloom Tech designs ribbon cables with controlled impedance and custom shielding, meeting EMI/EMC standards for consistent signal performance.

- Optimized Installation and Maintenance

Custom cable assemblies minimize wiring errors during installation and servicing, thanks to organized conductor paths and pre-terminated connectors. This structure reduces labor time and the risk of miswiring, benefiting quick-turn manufacturing and field maintenance.

- Support for Miniaturized and High-Density Applications

Ribbon cable assemblies accommodate compact electronic layouts, supporting pin counts exceeding 40 and small wire gauges below 28 AWG. Cloom Tech provides tailored insulation materials and flexible designs that fit tight enclosures in defense and aerospace equipment.

- Compliance with Industry Standards

Cloom Tech manufactures assemblies under UL and CSA regulations, providing traceable documentation and material certifications for applications in regulated markets such as automotive and medical technology. This compliance reduces qualification lead time for system approvals.

Common Applications of Ribbon Cable Assemblies

Custom ribbon cable assemblies deliver reliable, organized connections across high-density and multi-interface systems. Common sectors include electronics, automotive, medical, and telecom, where stable signal routing and compact design remain essential.

Electronics and Consumer Devices

Electronics and consumer devices use ribbon cable assemblies for internal data and power transfer between circuit boards. Examples like desktop computers, printers, and DVD players rely on these cables for motherboard-to-drive or display panel connections. Flat, parallel conductors optimize space and improve airflow in compact housings. Cloom Tech manufactures assemblies specified for unique board layouts, with length and connector options, supporting rapid installation and error-free matching to device schematics. Multi-pin IDC and socket connectors enable secure, repeatable installation in production lines. These attributes support miniaturized designs, reducing weight and assembly time in smartphones, digital cameras, and other compact products.

Automotive and Industrial Equipment

Automotive and industrial equipment integrate ribbon cable assemblies to link control modules, sensors, and user interfaces within tight dashboards or machinery panels. Modern vehicles use these cables in dashboard displays, infotainment systems, and airbag controls to support fast, clear signaling without signal noise. Industrial equipment, such as programmable logic controllers and robotics, benefit from assemblies built for vibration and temperature endurance. Cloom Tech engineers assemblies with reinforced insulation and designated EMI protections for rugged environments. Pin counts, jacket types, and custom labeling simplify installation and service in high-volume, repetitive manufacturing tasks. Organization reduces wiring confusion and allows fast troubleshooting, supporting continuous plant operation.

Medical and Telecommunications

Medical and telecommunications equipment depend on ribbon cable assemblies for miniature connection points and stable signal pathways. Imaging devices, diagnostic machines, and handheld monitors feature ribbon cabling for precise, traceable wiring that accommodates space-constrained chassis while meeting regulatory compliance. Telecom switches and routers use high-density assemblies to manage transmission lines across patch fields, minimizing crosstalk and latency. Cloom Tech validates cable construction to meet UL/CSA requirements and provides documented traceability for FDA or telecom certification. Customized assemblies maintain signal clarity under EMI-sensitive medical and telecom networks, supporting critical uptime and reliable diagnostics or data transfer.

Important Design Considerations

Custom ribbon cable assemblies require precise engineering choices to ensure reliable, high-performance connections in compact systems. Each decision impacts functionality, manufacturability, and long-term durability in demanding environments.

Material and Wire Selection

Material and wire selection impacts electrical and mechanical reliability of ribbon cable assemblies. Conductors typically use copper or tinned copper for stable conductivity and corrosion resistance. Insulation options include PVC for general use or PTFE and polyester for higher heat and chemical resistance. Engineers select wire gauges based on current-carrying requirements, device voltage ratings, and cable size limits, such as AWG 28 for signal lines or AWG 22 for power applications. Cloom Tech tests insulation compounds and conductor materials in Florida production facilities to maintain UL/CSA safety compliance and withstand operational stress for each order, supporting sectors like automotive and medical with strict regulatory standards.

Connector Options

Connector options must match system interfaces, assembly methods, and space constraints. Standard connectors include IDC (Insulation Displacement Connectors) for fast mass termination, D-sub for robust board or panel mating, and socket or header styles for modular connections in tightly packed assemblies. Selection criteria include pin counts—such as 10, 20, 34, or 50—for compatibility with PCB layouts, as well as locking mechanisms for shock and vibration resistance. Cloom Tech produces ribbon cables terminated with custom or industry-standard connectors, supporting integration for avionics, industrial controls, or data equipment, and verifying mating quality through automated testing.

Length and Configuration

Length and configuration affect signal integrity, routing ease, and mechanical flexibility within devices. Shorter assemblies maintain high-speed data quality, while precise lengths reduce slack and maintain airflow in confined enclosures. Designers can specify staggered pinouts, single- or double-row orientation, folding/branch styles, and breakouts for specialized routing in racks or panels. Cloom Tech fabricates assemblies to exact dimensional tolerances, aligning cable geometry with connector placement for robotics, server backplanes, or diagnostic equipment, minimizing installation time and error risk while supporting denser system layouts.

Choosing the Right Manufacturer

Selecting a manufacturer impacts ribbon cable assembly quality, delivery timelines, and regulatory compliance. Reliable manufacturers like Cloom Tech in Florida support engineers and OEMs by providing transparent fabrication processes and traceable material documentation.

Key factors include:

- Experience with Custom Designs: Manufacturers with experience like Cloom Tech produce assemblies for applications in sectors including automotive, medical equipment, and robotics. They offer support from prototyping through scaled production, ensuring cable assemblies meet project requirements.

- Material Testing and Certification: Effective suppliers use comprehensive material verification for conductors and insulators, supporting UL and CSA standards. Cloom Tech conducts full material audits with each order, establishing supply chain reliability for regulated industries.

- Precision Manufacturing Capabilities: Advanced equipment enables precise wire cutting, stripping, and termination. Cloom Tech leverages precision machinery and automated testing for assemblies supporting pin counts up to 64 and wire gauges from 28 to 18 AWG.

- Customization Support: Manufacturers offering engineering assistance, such as Cloom Tech, allow clients to specify length, pitch, connector type, and EMI shielding options. This approach enables adaptation for unique form factors and signal requirements.

- Quality Assurance and Service: Strict inspection processes, like those at Cloom Tech, provide 100% continuity and functionality testing. Documented quality checkpoints confirm correct assembly, minimizing installation errors and failures in the field.

Engineers evaluating manufacturers compare capabilities, standard compliance, and documentation support. Cloom Tech addresses requirements by providing tailored cable solutions, rapid prototyping, and detailed supply chain transparency for critical projects.

About Cloom Tech

Cloom Tech specializes in manufacturing custom wire harnesses and cable assemblies for various industries, including automotive, robotics, medical devices, and aerospace. Their services encompass design support from prototype to production, ensuring high-quality, durable, and reliable wiring solutions tailored to meet unique project requirements. Whether it’s a complex automotive harness or a precision medical device cable assembly, they are equipped to deliver customized solutions for diverse industrial applications.

Contact:

Ivy Zhao, Spokesperson

Phone: +1 863 434 8447

Email: [email protected]

Website: cloomtech.com

Location:

9251 NW 112th Ave, Medley, FL 33178, USA

Frequently Asked Questions

What are custom ribbon cable assemblies?

Custom ribbon cable assemblies are flat, multi-wire cables designed to provide organized and reliable connections between electronic components. They can be tailored in length, pin configuration, insulation, and connector type to fit specific system requirements.

What industries use custom ribbon cable assemblies?

Custom ribbon cable assemblies are widely used in electronics, automotive, medical, telecommunications, robotics, and aerospace sectors due to their flexibility, reliability, and ability to meet unique application needs.

Why choose a custom ribbon cable over a standard cable?

Custom ribbon cables offer a precision fit for specific applications, improved signal integrity, and optimal organization in dense electronic systems. They reduce installation time, minimize wiring errors, and can be adapted for miniaturized or high-density layouts.

How do ribbon cable assemblies help with signal integrity?

The parallel, flat layout of ribbon cable assemblies reduces crosstalk and electromagnetic interference (EMI), leading to clearer and more stable signal transmission between devices or circuit boards.

What customization options are available for ribbon cable assemblies?

Engineers can customize ribbon cables by selecting specific lengths, pin counts, insulation materials, connector types (such as IDC, D-sub, or socket), and additional features like EMI shielding to match system requirements.

What are common connector types used in ribbon cable assemblies?

Popular connector options for ribbon cable assemblies include Insulation Displacement Connectors (IDC), D-sub connectors, and socket-style connectors, which can be chosen based on the system interface and installation needs.

How do manufacturers test and ensure quality for custom ribbon cables?

Leading manufacturers like Cloom Tech perform rigorous material testing and comply with UL/CSA standards. They provide traceable documentation and certifications to guarantee quality, reliability, and regulatory compliance.

How do custom ribbon cables simplify installation and maintenance?

Their organized, flat design allows for easy identification of conductors, reducing wiring errors and labor time during installation or service. This structure is especially helpful in dense or miniaturized system layouts.

What materials are used in ribbon cable assemblies?

Most ribbon cables use copper or tinned copper conductors for reliable electrical performance. Insulation materials can vary, typically chosen based on environmental or electrical requirements.

Why is manufacturer selection important for ribbon cable assemblies?

Choosing a reputable manufacturer ensures timely delivery, precise fabrication, regulatory compliance, and comprehensive engineering support—all critical for high-performance and safety in complex electronic systems.